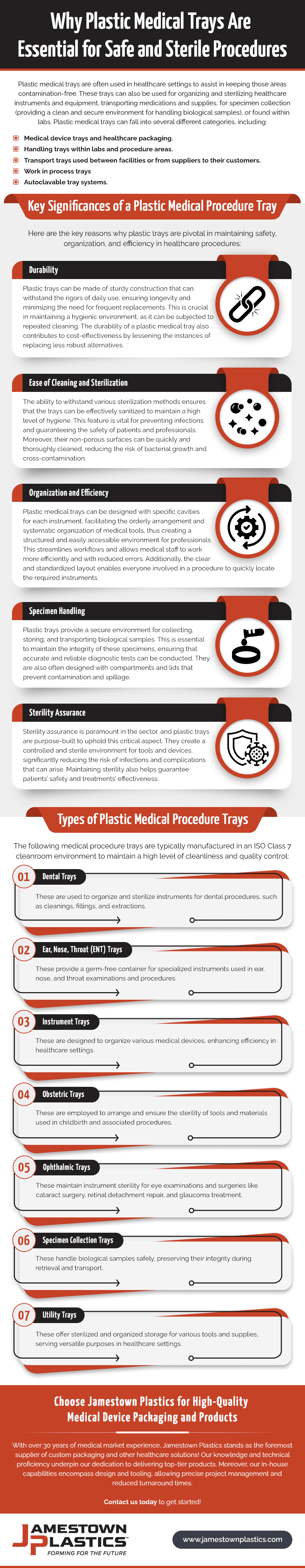

- Medical device trays and healthcare packaging

- Handling trays within labs and procedure areas

- Transport trays used between facilities or from suppliers to their customers

- Work in process trays

- Autoclavable tray systems

This article will delve into the importance of a plastic medical tray, specifically in ensuring safe and sterile procedures. It will also discuss the various types of procedure trays used in the healthcare industry.

Key Significances of a Plastic Medical Procedure Tray

Here are the key reasons why plastic trays are pivotal in maintaining safety, organization, and efficiency in healthcare procedures:

Durability

Plastic trays can be made of sturdy construction that can withstand the rigors of daily use, ensuring longevity and minimizing the need for frequent replacements. This is crucial in maintaining a hygienic environment, as it can be subjected to repeated cleaning. The durability of a plastic medical tray also contributes to cost-effectiveness by lessening the instances of replacing less robust alternatives.

Ease of Cleaning and Sterilization

The ability to withstand various sterilization methods ensures that the trays can be effectively sanitized to maintain a high level of hygiene. This feature is vital for preventing infections and guaranteeing the safety of patients and professionals. Moreover, their non-porous surfaces can be quickly and thoroughly cleaned, reducing the risk of bacterial growth and cross-contamination.

Organization and Efficiency

Plastic medical trays can be designed with specific cavities for each instrument, facilitating the orderly arrangement and systematic organization of medical tools, thus creating a structured and easily accessible environment for professionals. This streamlines workflows and allows medical staff to work more efficiently and with reduced errors. Additionally, the clear and standardized layout enables everyone involved in a procedure to quickly locate the required instruments.

Specimen Handling

Plastic trays provide a secure environment for collecting, storing, and transporting biological samples. This is essential to maintain the integrity of these specimens, ensuring that accurate and reliable diagnostic tests can be conducted. They are also often designed with compartments and lids that prevent contamination and spillage.

Sterility Assurance

Sterility assurance is paramount in the sector, and plastic trays are purpose-built to uphold this critical aspect. They create a controlled and sterile environment for tools and devices, significantly reducing the risk of infections and complications that can arise. Maintaining sterility also helps guarantee patients’ safety and treatments’ effectiveness.

Types of Plastic Medical Procedure Trays

The following medical procedure trays are typically manufactured in an ISO Class 7 cleanroom environment to maintain a high level of cleanliness and quality control:

- Dental trays:These are used to organize and sterilize instruments for dental procedures, such as cleanings, fillings, and extractions.

- Ear, nose, throat (ENT) trays:These provide a germ-free container for specialized instruments used in ear, nose, and throat examinations and procedures.

- Instrument trays: These are designed to organize various medical devices, enhancing efficiency in healthcare settings.

- Obstetric trays: These are employed to arrange and ensure the sterility of tools and materials used in childbirth and associated procedures.

- Ophthalmic trays: These maintain instrument sterility for eye examinations and surgeries like cataract surgery, retinal detachment repair, and glaucoma treatment.

- Specimen collection trays: These handle biological samples safely, preserving their integrity during retrieval and transport.

- Utility trays: These offer sterilized and organized storage for various tools and supplies, serving versatile purposes in healthcare settings.

Choose Jamestown Plastics for High-Quality Medical Device Packaging and Products

With over 30 years of medical market experience, Jamestown Plastics stands as the foremost supplier of custom packaging and other healthcare solutions! Our knowledge and technical proficiency underpin our dedication to delivering top-tier products. Moreover, our in-house capabilities encompass design and tooling, allowing precise project management and reduced turnaround times.

Contact us today to get started!